Innovations in Heat Resistant Materials: New Developments and Trends 2024

Are you worried about the unbearable heat of 2024? Have you ever thought how lasting and effective materials can help keep your environment cool?

Read on to understand the recent innovations in heat resistant materials and how they will shape the future.

Heat Resistant Materials – Properties and Characteristics

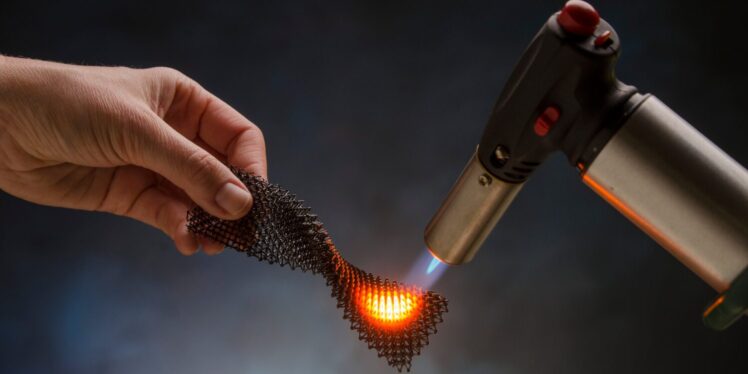

Heat resistant materials are materials that have been engineered to withstand high temperatures and minimize heat transfer. These materials typically possess higher melting points, good thermal stability and insulation, and the ability to resist large temperature changes. Their properties are determined by their composition, structure and microstructure. Common examples of heat resistant materials include ceramics such as alumina, silicate glasses, refractory bricks and concretes, alloys such as stainless steel and nickel-based alloys, plastics such as polyimide or polyvinylchloride (PVC), elastomers such as chlorosulfonated polyethylene (CSPE) or silicone rubbers. Fire sleeve, as well as other types of protective materials such as heat-resistant coatings, insulation materials, and fire blankets, can provide additional protection against high temperatures and flames to prevent damage to equipment and ensure the safety of individuals in various industries.

Source: hackaday.com

Heat resistance is usually determined by four major characteristics including; thermal shock resistance – the ability of a material to resist sudden changes in temperature; temperature limit – the highest temperature a material can withstand without distortion or burning; specific heat – the amount of heat needed to raise the temperature of unit mass by one degree Celsius; thermal conductivity – the rate of heat transfer through it when a temperature difference is applied across its boundaries.

Other important qualities include chemical corrosion resistance, which prevents degradation due to exposure to chemicals while maintaining strength; wear resistance which prevents wear caused by friction during handling and fabrication; radiation protection which resists damage due to ionizing radiation exposure; flame retardance which reduces flammability for safety applications.

Automotive and Aerospace Industries

One of the most crucial areas where these materials are utilized is in the automotive and aerospace industries. High engine temperatures and the need for rapid ascend to high altitudes make these two industries extreme users of these materials.

Almost all major components, from exhaust systems to brake systems, require using heat resistant materials. Additionally, more modern applications like aircraft wings and turbofan engines necessitate advanced heat resistant surfaces. The basics of automotive heat resistant material utilization are similar—from mufflers and gearboxes to fuel injection systems.

Source: youtube.com

For both automotive and aerospace industries, there is an increasing focus on cutting-edge innovations that can bring higher levels of performance than traditional solutions. For instance, carbon fiber reheat systems are becoming better at resisting high operation temperatures while sporting super-light characteristics that greatly reduce the weight of aircraft and cars respectively.

In addition, 3D printed components have been proven capable of withstanding extreme temperatures while being built as per customized specs with great precision aspects in mind—making them perfectly suited for both automobiles and aircraft that require highly precise components along with protection against heat damage or deformation over time.

Manufacturing and Construction

They are important components in manufacturing and construction, helping to prevent overheating or fires caused by extreme temperatures. In 2025, advances in research will continue to lead to innovative applications of heat resistant materials across a variety of industries.

Recent advancements in it include developments in salt-heated ceramic composites, copper diamond matrix composites and Pyroceram. These items can be used for a variety of construction and manufacturing purposes including insulating tanks, ovens and furnace linings, as well as protecting delicate systems from fire damage. Innovations in heat resistant materials are characterized by higher melting points and better coefficient of thermal expansion (CTE), mechanical strength, electrical properties, thermal shock resistance and durability.

Source: aspirets.com

Other modern advancements include enhanced silicone compounds that are stronger than traditional silicone due to its ability to withstand extreme temperatures more effectively than other polymers when combined with glass fiber reinforcements. 3D printing has also allowed manufacturers the ability to easily create custom heat resistant parts quickly and cost effectively for applications including turbine blades for aerospace engines.

In addition to the development of new products that can withstand high levels of temperature without combustion or damage, advances have led to better understanding of how these products interact under extreme conditions. For example, engineers now have an improved understanding of climate effects on the reliability of ceramic coated steel parts as well as how dissimilar material compositions may affect durability when subjecting them to different kinds of weather conditions over an extended period of time. This new knowledge has enabled manufacturers greater flexibility when selecting materials for various construction projects as well as providing a degree of predictability with regard to product life expectancy under certain environmental conditions without having extensive knowledge about them upfront.

Emerging Trends in Heat Resistant Materials

Source: toistudent.timesofindia.indiatimes.com

They are essential to a broad range of applications within the modern tech industry and other high temperature industries such as aerospace, transportation, defense and power generation. As technology evolves, the requirements for next-generation materials become more stringent. The need for highly heat-resistant materials that can withstand the rigors of high temperatures while offering superior structural performance is growing rapidly. New advancements in heat resistant material technology are driving advances in energy efficiency, miniaturization and long-term reliability.

In this article we review some of the most recent and promising developments in heat-resistant material technology with a focus on emerging trends for 2024 and beyond. We explore some of the key criteria used to evaluate heat resistant materials, covering aspects such as thermal management, coefficient of thermal expansion (CTE) performance, maximum operating temperature (MOT), tensile strength and flexural strength to name a few. Additionally, we discuss some interesting novel approaches that could potentially disrupt current design standards while improving overall system performance.

Conclusion

In conclusion, the advances in heat resistant materials have been nothing short of remarkable. From fire-resistant fabrics to insulation that can withstand extreme temperatures, these materials are now being used in a wide variety of applications. As technology continues to evolve and new applications for these types of materials become available, it is likely that we will see even more developments over the next few years. The future looks bright for heat resistant material innovations, and we look forward to seeing what comes next!